Pain Points

Inefficient WIP flow of production process

Lack of the process tracking and data

Difficulty of product process quality tracing

Low production line balance and high production costs

Solution Overview

Based on the production process, the IIoT technology such as barcode, RFID, positioning, data mining, visual AI, etc. is used to collect the identity, status, location, quantity, process and other comprehensive data of the objects (personnel, materials, pallets, forklifts, etc.) to complete the missing process data. Through multi-dimensional statistical analysis of process data, it provides strong support for production resource scheduling, dynamic optimization, and management decision.

Solution Targets

Real-time Data Collection

Through real-time data tracking of WIP, tracing, analysis, and continuous improvement of quality problems, to realize optimization of production efficiency and enhancement of site management.

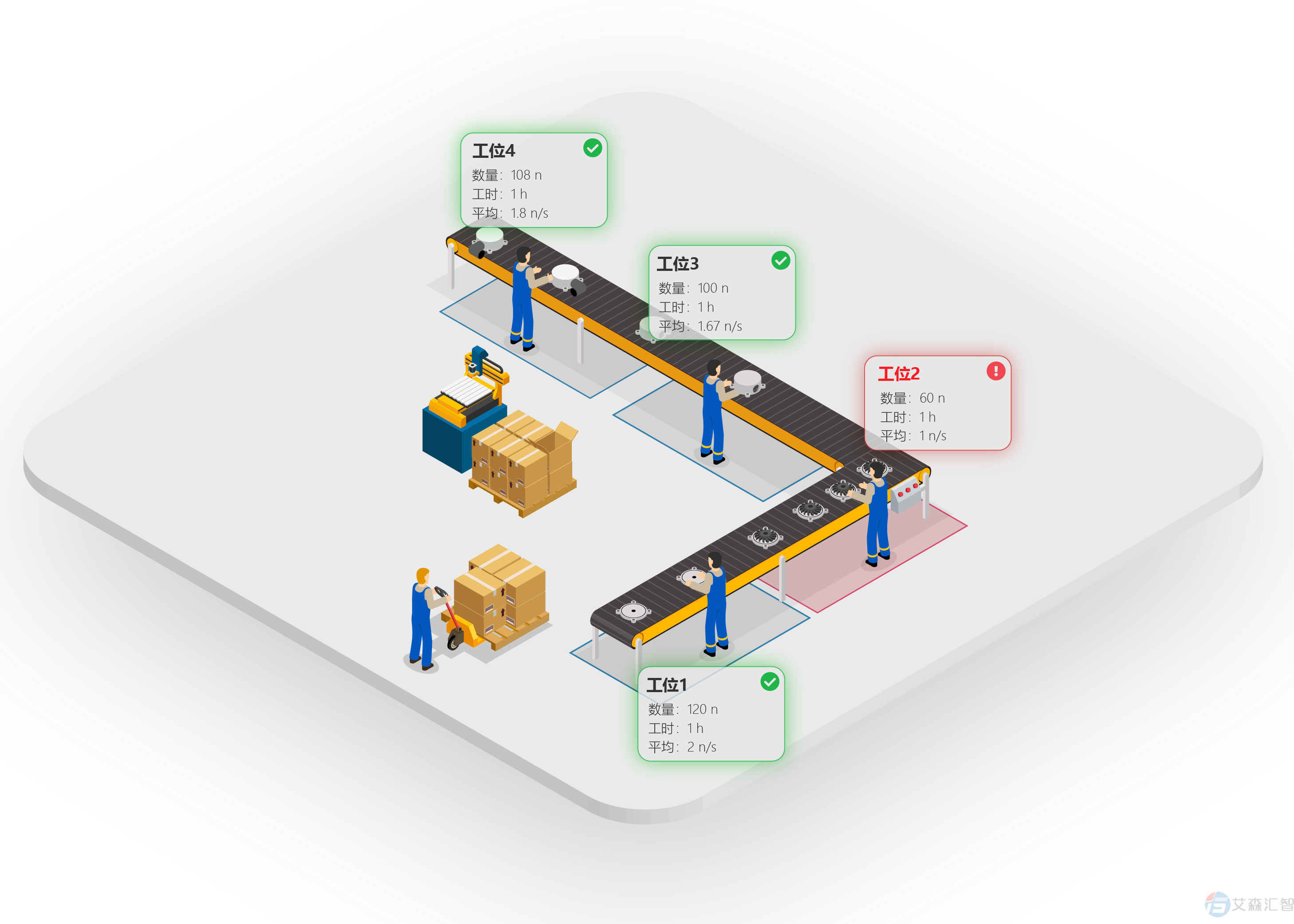

Evaluation of Production Capacity

Through process beat analysis, capacity balance rate analysis, execution and plan comparison analysis, etc. to maximize production capacity and support for production management decisions.

Intelligent Management Realization

Data integration of different systems combines with data visualization enable high efficiency of site management, digitization of production process, real-time tracking of orders and intelligence of management.

WIP Location Collection

Based on i-LDFP, the IoT technology (UWB, BLE, RFID, Barcode, etc.,) is used to collect the location and code of WIP, vehicles and packages etc., to complete the missing process data.

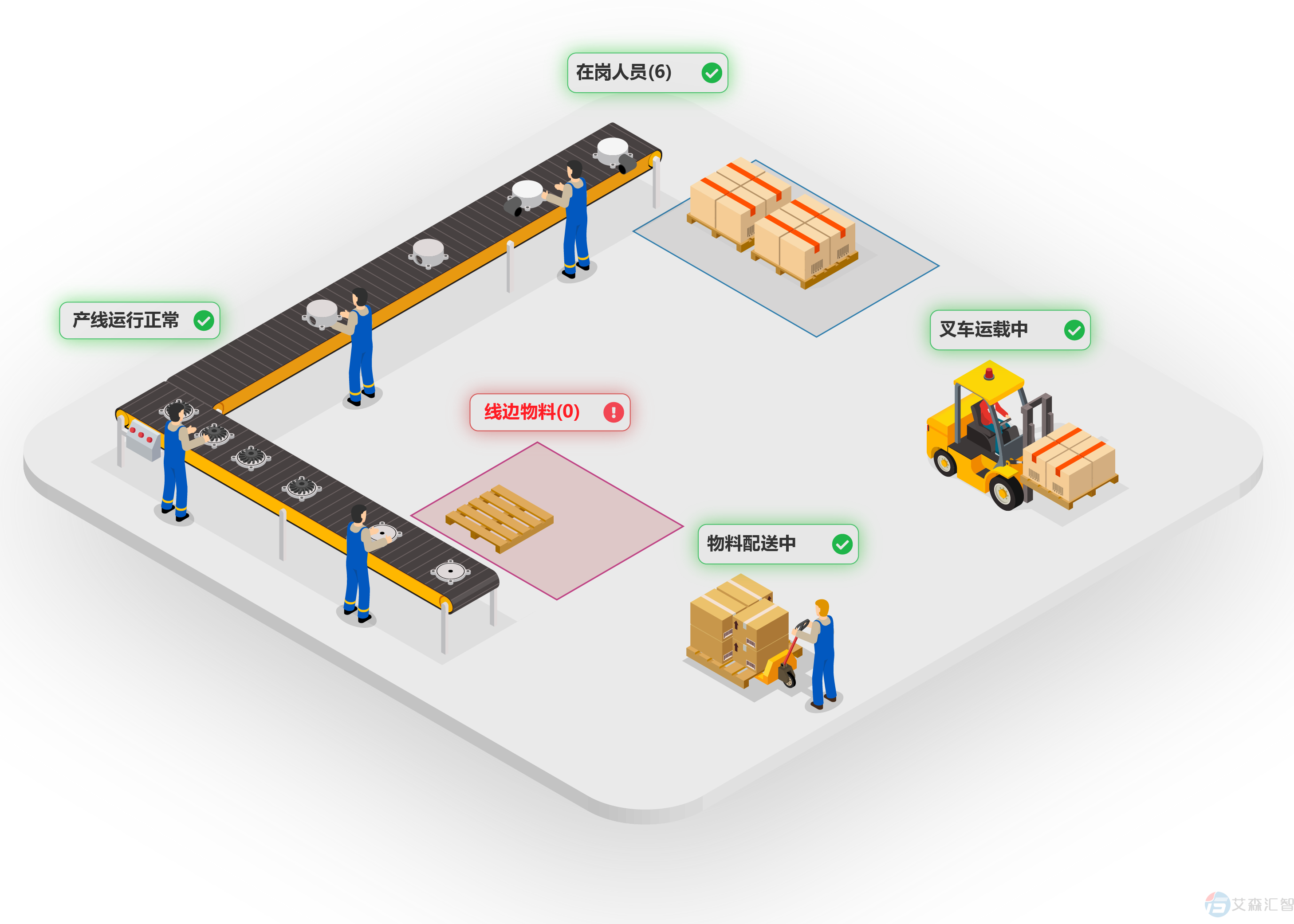

WIP Visual Tacking

The tracking of the quantity, location and status of WIP in each process is visually presented based on GIS location service.

Abnormal situations are handled in time to improve the flow efficiency.

WIP Dynamic Analysis

Dynamically optimize the resource allocation through process data analysis. Use objective production data to support production decision-making and digital management upgrading.

Benefits and Value

In Time

WIP tracking time reduced to 0

Increase Efficiency

Improve flow efficiency, accuracy and optimize resource allocation

Reduce Costs

Shorter lead times and lower operating costs

Applicable Scenarios

Focus on business scenarios, enable digital operation

Automotive Assembly

Track the process flow of the frame, main engine and other products in the final assembly process

Machining

Track the process flow in machining scenarios for WIP, materials, pallets, etc.

SMT

Track the distribution of materials and the flow of WIP in SMT production