Platform Panoramic

The Location Data Fusion Platform (i-LDFP) is designed to create a one-stop solution platform for real-time locating scenarios.

The i-LDFP is committed to creating a comprehensive of location data solutions for enterprises, through diversified location data collection and fusion computing to eliminate location data information islands. The platform provides standard open location data service API, which can be connected to the data center or business system. Combined with the corresponding BI system, it provides data support for location intelligence (LI) and helps enterprises make intelligent decisions.

Platform Introduction

Platform Introduction

The platform is integrated with RTLS, BD, GIS, IoT, BI, SaaS+ and other technologies. Through the core polymorphic comprehensive locating technology and standardized location fusion computing engine, user can build stable and reliable applications of LBS.

Drives Collection Computing Analysis Visualization

Why We Choose i-LDFP?

The first location fusion platform in China that complies with omlox standard

Data unitization & Standardization

Location data collection and fusion computing under unified interface standards

Data fusion + Visualization

“Location + Business” data fusion to eliminate data islands

LI Assists Management Decisions

Location data empowerment, value mining, cost reduction and efficiency improvement

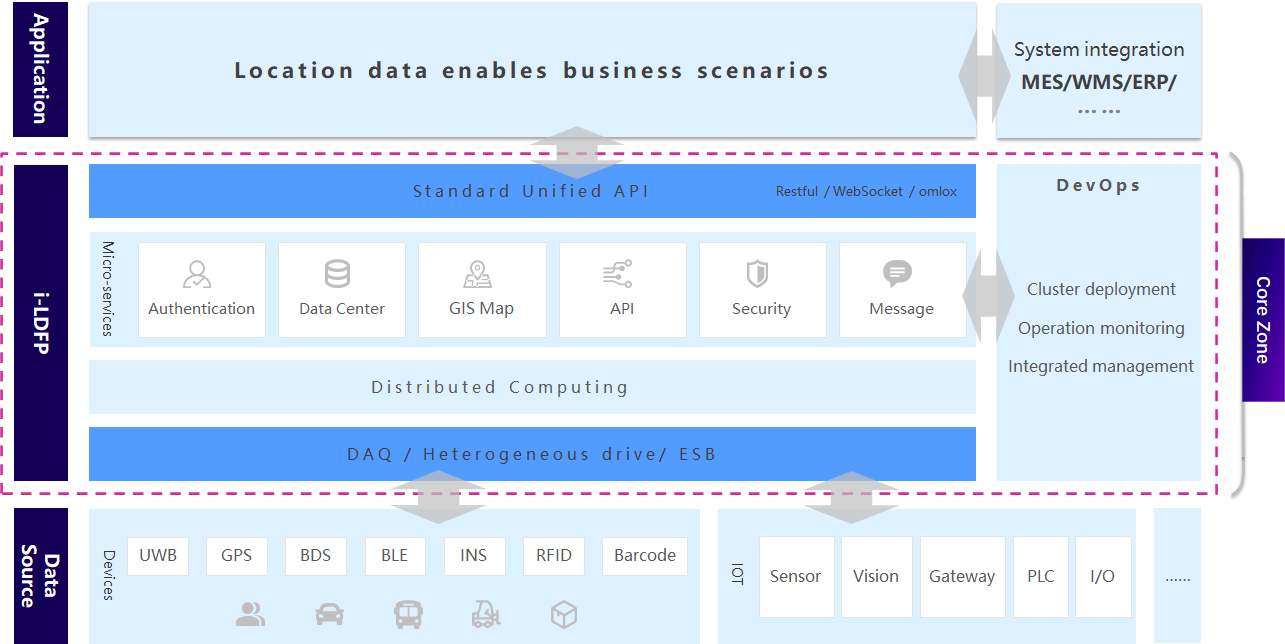

Platform Architecture

Micro-Architecture & Cloud Services

Platform Functions

Continued iteration of product functions to strengthen the base of location data services and enable data value

Map

- Tile

- Customised

- 3D

- Upload

- Configure

Object

- Tag

- Anchor

- Camera

- Sensor

- Equipment

Area

- Mapping

- Algorithm

- Alarm

- Linkage

Real-time Location

- Location Overview

- Location Search

- Online Statistics

- Real-time Heatmap

Historical Location

- Historical Trajectory

- Scattershot Analysis

- Point HeatMap Analysis

- Data HeatMap Analysis

Log Service

- Location Data

- Area In/Out

- Alarm Log

- Message Log

Extended Integration

- Map Interface

- POI Interface

- RTL Interface

- Area In/Out Interface

- Alarm Interface

- Message Service

Platform Advantages

Business scenario-oriented efficient accumulation and deep application of data assets

Microservice & Multi-Application

An application architecture designed around the characteristics of location data services

Massive Data Access

Supports high concurrency real-time processing of massive location data streams

High Scalability & Availability

Supports multiple services, technologies, devices, and scenarios

Core Algorithm Model

Independent R&D of graphics, behavior, feature analysis and other location core algorithms

Continuous Iteration

Continuous iterative innovation delivery capability and business continuity

Value Driving

Data drives management decisions, business operations and innovation

Compare with Traditional Projects

Platform service helps you focus on business development

| - | Traditional Projects | Platform Projects |

|---|---|---|

| R&D Costs | Higher | Lower |

| R&D Capability | Higher | Lower |

| Project Cycle | Longer | Shorter |

| Scalability | Lower | Higher |

| Operation Costs | Higher | Lower |

| Service Capabilities | Incontinuous | Continuous |

| Project Benefits | Lower | Higher |

Platform Achievements

500+ Partners、2000+ Cases

0 Billion

0 +

0 +

Applicable Scenarios

Steel / Chemical / Petroleum

A safety control platform for personnel on duty based on location technology is built to enhance the safety of production process management through abnormal monitoring and automatic inspection.

Automotive / Discrete Manufacturing

By collecting and tracking the real-time location of products to realize the monitoring of production schedule. The location data can also be integrated with business systems to eliminate information islands.

Steel / Chemical

The Standardized on-site SOP for safety operations combined with location tracking to monitor operation process and data, it can ensure safety while improve operation efficiency.

Warehousing / Logistics

By collecting the location of forklifts and data integration with the warehousing system to realize the automatic inbound and outbound of products and help achieve digital upgrading and intelligent empowerment for enterprise.

Use Cases

Focus on business scenarios, enable digital operation

WIP Tracking

By collecting and tracking the locations of WIP, the production process is dynamically optimized to achieve process quality tracing and improve flow efficiency.

Automatic Integration of Flat Warehouse

Location tracking and analysis of materials, vehicles/pallets and forklifts enable automatic inbound and outbound management and improve storage operation efficiency.

Safety in Hazardous Chemical Production

By building an integrated management platform to enhance the control and management of the safety production process and realize the upgrade of digital intelligence.