System Introduction

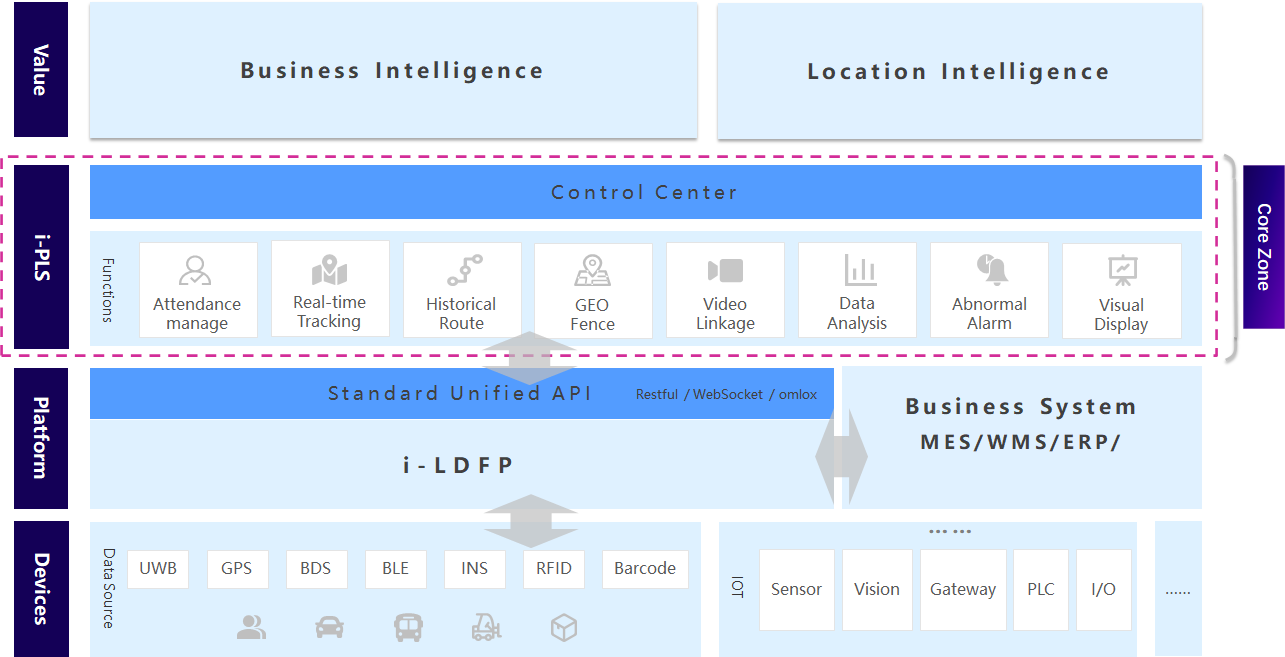

i-PLS is a set of Integrated Positioning Management System based on WEB technology after years of market development, project operations and verifications.

Combined with the self-developed i-Map engine, the system can apply data analysis and display them visually through 2D/3D mode for end users.

Based on i-LDFP, it can access location data of multiple positioning technologies and be integrated into other enterprise management systems such as MES and WMS to finally realize the informatization, intellectualization, integration and visualization comprehensive management for enterprise.

Core Functions

Business scenario oriented, supports N+ extended applications

Real-time Tracking

Real-time location visually tracking of objects such as people, cars, materials etc.

Historical Route

Search and playback of location data in a historical period

Geo Fence

Entry and exit events or abnormal behavior monitoring and alarm

Data Analysis

Statistics of online locating objects and regional dynamic heat map analysis etc.

Attendance Management

Automatic attendance analysis and management based on location data

Video Linkage

Trigger linkage with surveillance video around location data

Abnormal Alarm

All kinds of abnormal alarms, message pushing services, etc.

Visual Display

A comprehensive display of the on-site layout, locating objects tracking etc.

System Architecture

System Advantages

Fitting Scenarios, Attentive service

Virtualization & Distributed

Distributed deployment based on B/S

Supports business processing anytime, anywhere

Multi-User & Multi-Terminal

Supports multi-user login management

Supports multi-terminal (PC, mobile, tablet) access

Secure, Stable, Reliable

Complies with OWASP security coding specification

Easy deployment, easy maintenance and highly secure

Open & Expandable

Supports secondary development and business expansion

Easy to integrate with enterprise tripartite systems

Applicable Scenarios

Focus on business scenarios, digital management and intelligent operation

Bus assembly positioning management

Vehicle locations on the assembly line are collected and integrated with the MES system. Through multi-dimensional analysis of production progress, cycle time and capacity to improve production capacity and optimize production efficiency.

WIP tracking management

By collecting and tracking the locations of WIP, the production process is dynamically optimized to achieve process quality tracing and improve flow efficiency.

Safety in hazardous chemical production

By building an integrated management platform to enhance the control and management of the safety production process and realize the upgrade of digital intelligence.